Standard:

Adheres to API 5L, the specification for line pipe used in the petroleum and natural gas industries.

Fabrication :

Made using the Submerged Arc Welding (SAW) process, creating strong, high-quality welds.

Types of SAW:

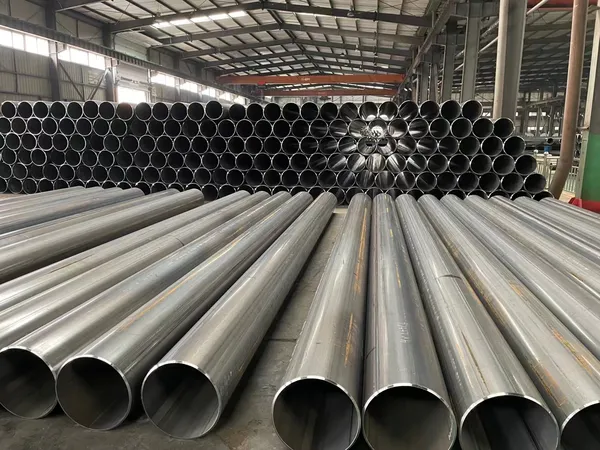

Includes Longitudinal SAW (LSAW) for straight seams and Helical SAW (HSAW) for spiral seams.

LSAW (Longitudinal SAW):

Produced by forming steel plates into a round shape and welding the seam along the pipe’s length. Also known as JCOE pipe based on the manufacturing steps (J-shape, C-shape, O-shape, and Expansion). Typical diameters range from 20 to 48 inches.

SSAW / HSAW (Spiral/Helical SAW):

Manufactured by welding steel coils spirally into a helix shape. This method allows for the production of extremely large diameters, often up to 100 inches or more.

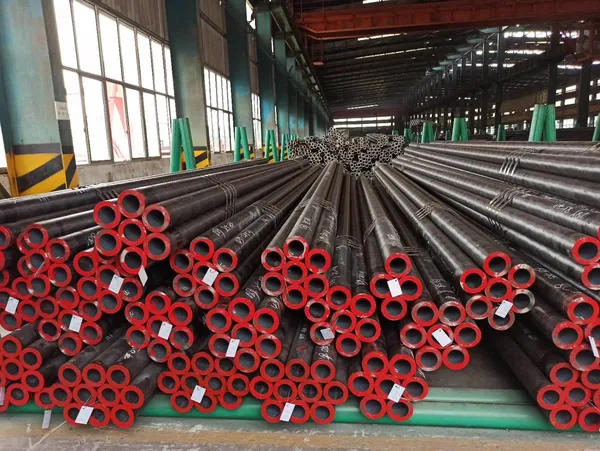

DSAW (Double Submerged Arc Welded):

A technique where the pipe is welded on both the inside and outside to ensure high density and weld integrity.

Grades:

Available in grades from B (e.g., Grade B) to high-strength X grades (X42, X52, X60, X65, X70, X80, X100, X120), indicating yield strength.

PSL Levels:

Comes in Product Specification Levels (PSL1, PSL2) with varying requirements for mechanical and chemical properties, with PSL2 being more stringent.

Production Range:

Applications :

Used for onshore, offshore, and sour (H2S) service pipelines due to its durability and resistance to corrosion and cracking.

Propriétés :

Offers high tensile strength, dimensional accuracy, and resistance to high pressure and temperature.In essence, an API 5L SAW pipe combines the stringent material and quality requirements of API 5L with the robust, large-diameter fabrication capability of the Submerged Arc Welding process for critical energy transport.

Applications & Advantages:

Oil & Gas Transport: Primarily used for long-distance, high-pressure onshore and offshore transmission pipelines.

Deep Penetration: SAW welding offers deeper weld penetration and higher deposition rates compared to other methods, making it suitable for thick-walled pipes.

Harsh Environments: Special variations are available for Sour Service (H2S corrosive environments) and Offshore Service.

Durability: Features high tensile strength, good toughness at low temperatures, and resistance to stress corrosion cracking