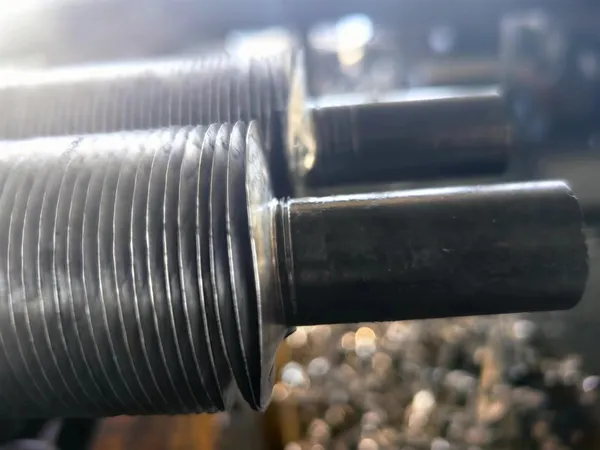

4140 Steel Uses:

AISI SAE 4140 alloy steel can be made into steel tube, and has many uses in the aerospace, oil and gas and automotive industries, typical uses are thin-walled pressure vessels, forged gears and shafts (Motor shafts, pump shafts, hydraulic shafts, etc.), spindles (lathe spindles, milling spindles, etc.), collars, clamps, high strength bolts, valve bonnet, screws, nuts, worms, collets, torsion bars and various carburized parts.

“We can supply material on urgent delivery basis because of large stock.The Tubes can be supplied with EN 10204 EN 3.1 and EN 3.2 certifications.We can provide Third Party Inspection from any reputed inspection agency.”

The table below lists AISI 4140 chemical composition:

| AISI SAE 4140 Chemical Composition (%) | ||||||||

| Steel (UNS) | C | Si | Mn | P (≤) | S (≤) | Cr | Mo | Ni |

| 4140 (G41400) | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.035 | 0.040 | 0.80-1.10 | 0.15-0.25 | – |

AISI 4140 Steel Mechanical Properties:

| Steel | Tensile strength, Mpa (ksi) | Yield strength, Mpa (ksi) | Elongation in 50 mm (2 in), % | Reduction in area, % | Hardness (HB) | Sample diameter | Conditions |

| AISI 4140 | 1020 (148) | 655 (95) | 17.7 | 46.8 | 302 | 25.4mm (1 in.) | Normalized at 870 °C (1600 °F) |

| 655 (95) | 414 (60) | 25.7 | 56.9 | 197 | Annealed at 815 °C (1500 °F) | ||

| 1075 (156) | 986 (143) | 15.5 | 56.9 | 311 | Water quenched from 845 °C (1550 °F) and tempered at 540 °C (1000 °F) |

SAE 4140 Physical Properties:

Notes: 10-6/K = 10-6.K-1 = (µm/m)/°C

| Material 4140 coefficients of linear thermal expansion | ||

| Temperature, °C (°F) | Value (10-6/K) | Treatment or condition |

| 20-100 (68-212) | 12.2 | Oil hardened, tempered |

| 20-200 (68-392) | 12.6 | |

| 20-400 (68-752) | 13.6 | |

| 20-600 (68-1112) | 14.5 | |

| 4140 thermal conductivity | ||

| Value (W/m·K) | Temperature, °C (°F) | Treatment or condition |

| 42.7 | 100 (212) | Hardened & tempered |

| 42.3 | 200 (392) | |

| 37.7 | 400 (752) | |

| 33.1 | 600 (1112) | |

| AISI / SAE 4140 Specific Heat | ||

| Value (J/Kg·K) | Temperature, °C (°F) | Treatment or condition |

| 473 | 20-200 (68-392) | Hardened & tempered |

| 519 | 20-400 (68-752) | |

| 561 | 20-600 (68-1112) | |

| Mateiral 4140 Electrical Resistivity | ||

| Value (μΩ· m) | Temperature, °C (°F) | Treatment or condition |

| 0.22 | 20 (68) | Hardened & tempered |

| 0.26 | 100 (212) | |

| 0.33 | 200 (392) | |

| 0.48 | 400 (752) | |

| 0.65 | 600 (1112) | |

Material 4140 Steel Heat Treatment

The following table shows AISI 4140 steel heat treatment, Rockwell hardness.

| Material 4140 Heat Treat | Temperature, °C (°F) | 4140 steel hardness | Cooling/Agent |

| Normalizing | 870 (1600) | 302 HB | Air |

| Annealing | 790-845 (1455-1555) | 197 HB | Furnace cooling |

| Quenching | 830-845 (1525-1555) | Oil | |

| Tempering (2 hour) | 205 (400) | 58 HRC | Oil hardening |

| 260 (500) | 54 HRC | ||

| 315 (600) | 50 HRC | ||

| 370 (700) | 47 HRC | ||

| 425 (800) | 45 HRC | ||

| 480 (900) | 40 HRC | ||

| 540 (1000) | 35 HRC | ||

| 595 (1100) | 33 HRC | ||

| 650 (1200) | 28 HRC |

Normalizing:

4140 alloy steel is typically normalized at 870 °C (1600°F), and should be cooled at a specified temperature in still air.

Spheroidizing Annealing

For spheroidizing annealing of 4140 alloy steel, it needs heat treated to 749 °C (1380 °F), followed by slowly cooling to 666 °C (1230 °F) at a rate of 6 °C (10 °F)/hour, or rapid cooling to 675 °C (1250 °F) for isothermal annealing.

Full Annealing

Heat treatment to 845 °C (1555 °F), slow cooling from 755 °C (1390 °F) at a rate of 14 °C (25 °F)/hour to 665 °C (1230 °F), or rapid cooling to 675 °C (1250 °F) for 5 hours isothermal annealing.

Tempering

Tempering temperature of 4140 alloy steel can be from 204-649 °C (400-1200°F) after normalizing and oil quenching, and the corresponding Rockwell hardness can be obtained.

Forging

Material 4140 forging temperature is about 1232 °C (2250 °F).

Welding of 4140 Steel

All common arc welding processes, such as (SAW, SMAW, FCAW, GMAW, GTAW) can be used to weld 4140 alloy steel, but in order to prevent cracking, it must be preheated to 170-350 °C (350-650 °F) before welding, preheating inter pass temperature depends on the section thickness of the steel.

Equivalent Material.

AISI 4140 equivalent material is listed in the table below:

| AISI 4140 Equivalent Material | |||||||||

| USA | European Union | China | Japan | ISO | |||||

| Estándar | Grade (UNS) | Estándar | Grade (Steel Number) | Estándar | Grado | Estándar | Grado | Estándar | Grado |

| AISI SAE; ASTM A29/A29M | 4140 (G41400) | EN 10083-3 | 42CrMo4 (1.7225) | GB/T 3077 | 42CrMo | JISG 4105 | SCM440 | ||