ASTM A335 P91 (also known as ASME SA335 P91) is a high-performance seamless ferritic alloy-steel pipe engineered for high-temperature and high-pressure service. Often referred to as “9 Cr 1 Mo” steel, it is a staple in power generation and petrochemical industries due to its exceptional creep strength and thermal stability.

Also conforms to ASME SA335 Grade P91.

Designated as UNS K91560.

Standard and Grades: ASTM A335 / ASME SA335 Grade P91

Material types: Chrome Moly Alloy

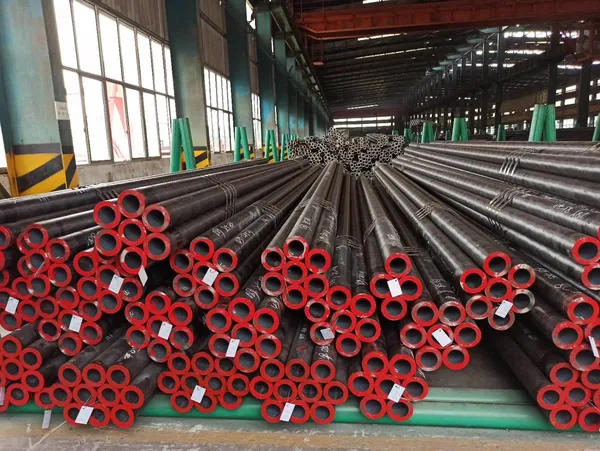

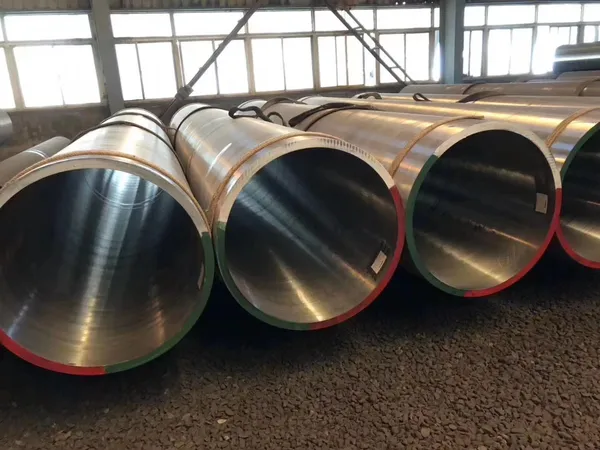

Manufacturing types: Seamless hot rolled

Sizes: 1/2” to 40” DN25 to DN1000

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160,ect

Length: 6 meters, 12 meters or customized.

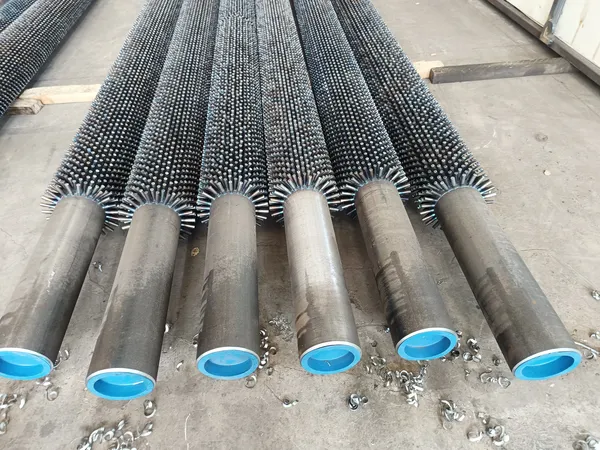

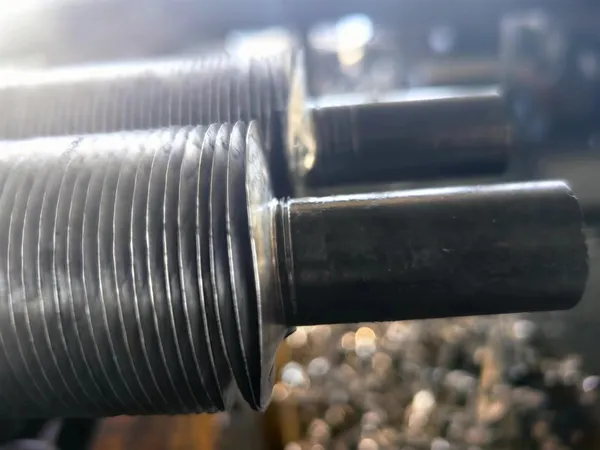

Surface treatment: Polished, Varnished, 3LPE, FBE,FINNED

Ends: PE (Plain End), BE (Beveled Ends)

Key Technical Specifications (Standards):

Kompozisyon: Primarily consists of 9% Chromium (for oxidation resistance) and 1% Molybdenum (for creep strength), with additions of Vanadium and Nitrogen to enhance mechanical properties.

İmalat: Seamless, either hot-finished or cold-drawn.

Mechanical Properties:

Tensile Strength: Minimum 585 MPa (85 ksi).

Yield Strength: Minimum 415 MPa (60 ksi).

Hardness: Typically ranges from 190 to 250 HBW.

Heat Treatment: Critical for achieving its properties; it involves normalizing (approx. 1050°C) and tempering (approx. 760°C).

Operating Range: Designed for continuous operation at temperatures up to 600°C–650°C.

Performance Advantages:

High Creep Strength: Classified as a Creep Strength Enhanced Ferritic (CSEF) steel, it maintains structural integrity under prolonged high-temperature stress.

Reduced Wall Thickness: Compared to older grades like P22, P91’s higher strength allows for a wall thickness reduction of nearly 50%, leading to lighter hangers and faster welding.

Thermal Fatigue Resistance: Offers significantly higher thermal fatigue life, enabling more efficient power plant operations.

Common Applications:

Power Generation: Main steam piping, hot reheat piping, and boiler headers.

Petrochemical: Refineries and chemical processing units involving high-temperature fluids.

Industrial: Heat exchangers, superheaters, and pressure vessels.

Differences Between Type 1 and Type 2:

Modern specifications often distinguish between Type 1 and Type 2 P91. Type 2 generally features stricter controls on trace elements (such as Manganese, Sulfur, and Silicon) and nitrogen content to provide more consistent mechanical properties and improved weldability.