Standard:

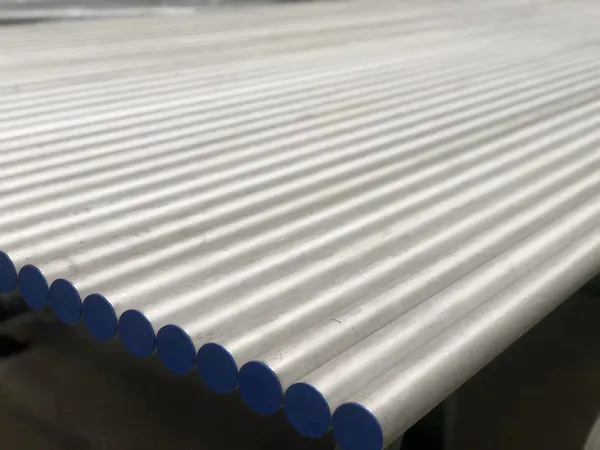

ASTM B163 Inconel 600 (UNS N06600) Seamless Tube for use in condenser and heat-exchanger service

ASME SB163 / Seamless Nickel and Nickel Alloy Condenser and Heat Exchanger Tubes supplier

ASTM B163,Inconel 600 (UNS N06600) Seamless Tube – Quick Details:

Manufacture: Seamless process ,annealed

Wall thickness(WT): 1.24 mm – 40.49 mm.

Outer diameter (OD): 10.3 mm – 406.4 mm

Delivery Condition: Pickled&Annealed, Polished, Bright Annealed.

Length: 20FT or 40FT,specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info:

Port of Shipment: Any Port

Payment Terms: T / T, LC

Delivery: 25 days after payment

Surface: Tubes will be varnished to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

Chemical Composition of ASTM B163 Inconel 600 (UNS N06600)

| Composition,% | |

| Sınıf | N06600 |

| Nicke | 72.0 min B |

| Copper | 0.5 |

| Molybdenum | … |

| Iron | 6.0–10.0 |

| Manganese | 1.0 |

| Carbon | 0.15 |

| Silicon | 0.5 |

| Sulfur | 0.015 |

| Chromium | 14.0–17.0 |

| Aluminum | … |

| Titanium | … |

| Phosphorus | … |

| Cerium | … |

| Zirconium | … |

| Yttrium | … |

| Boron | … |

| Cobalt | … |

| Columbium(Nb) | … |

| Tungsten | … |

| Nitrogen | … |

B Element shall be determined arithmetically by difference.

Mechanical Properties and Other Requirements of of ASTM B163 Inconel 600 (UNS N06600)

| Material and Condition | Tensile Strength, min, ksi (MPa) | Yield Strength (0.2 % Offset), min, ksi (MPa) | Elongation in 2 in. or 50 mm (or 4 D) min, % | Rockwell Hardness (or equivalent) for annealed ends A |

| Nickel-chromium-iron alloys:Annealed alloy UNS N06600 | 80 (552) | 35 (241) | 30 | … |

Permissible Variations(tolerance)in Outside Diameter and Wall Thickness of Condenser and Heat Exchanger Tubes

| Material | Nominal Outside Diameter, in. (mm) | Permissible Variations A | |||||

| Outside Diameter, in. (mm | Wall Thickness,% | ||||||

| + | − | Average Wall | Minimum Wall | ||||

| + | – | + | – | ||||

| UNS N02200, UNS N02201, and UNS N04400 | 1 ⁄ 2 to 5 ⁄ 8 (12.7 to 15.9), excl | 0.005 (0.13) | 0 | 12.5 | 12.5 | 25.0 | 0 |

| 5 ⁄ 8 to 1 1 ⁄ 2 (15.9 to 38.1), incl | 0.005 (0.13) | 0.005 (0.13) | 10.0 | 10.0 | 20.0 | 0 | |

| over 1 1 ⁄ 2 to 3 (38.1 to 76.2), incl | 0.010 (0.25) | 0.010 (0.25) | 10.0 | 10.0 | 22.0 | 0 | |

| UNS N06600, UNS N06601, UNS N06690, UNS N06045, UNS N06025, UNS N06603, UNS N06696, UNS N08800, | 1 ⁄ 2 to 5 ⁄ 8 (12.7 to 15.9), excl | 0.005 (0.13) | 0.005 (0.13) | 12.5 | 12.5 | 25.0 | 0 |

| 5 ⁄ 8 to 1 1 ⁄ 2 (15.9 to 38.1), incl | 0.0075 (0.19) | 0.0075 (0.19) | 10.0 | 10.0 | 20.0 | 0 | |

| over 1 1 ⁄ 2 to 3 (38.1 to 76.2), incl | 0.010 (0.25) | 0.010 (0.25) | 10.0 | 10.0 | 22.0 | 0 | |

Testing Standard :

Chemical Analysis

Mechanical Properties

Hardness test

NDE: UT / RT / ET

TUV / DNV / SGS

The Certificate :

EN 10204 3.1 / 3.2