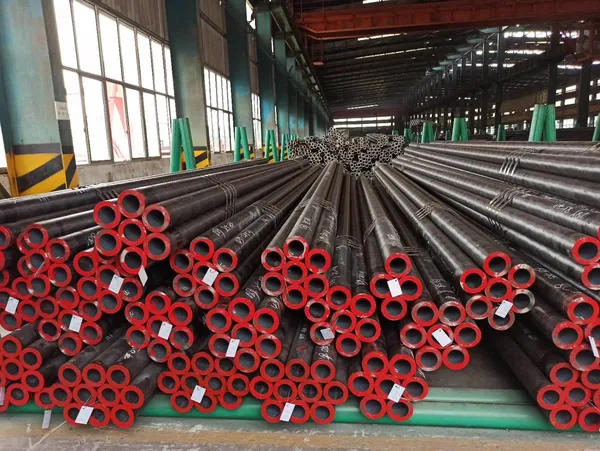

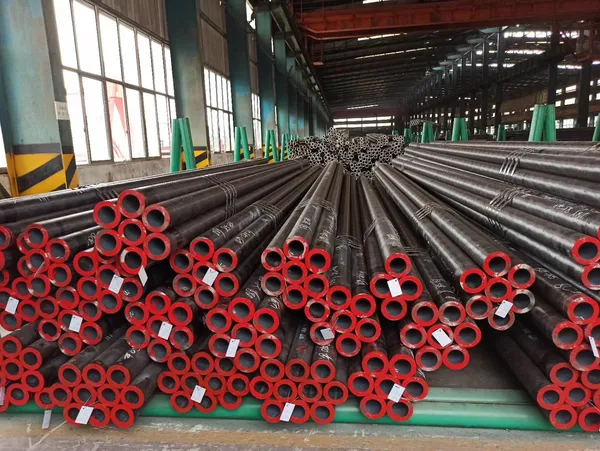

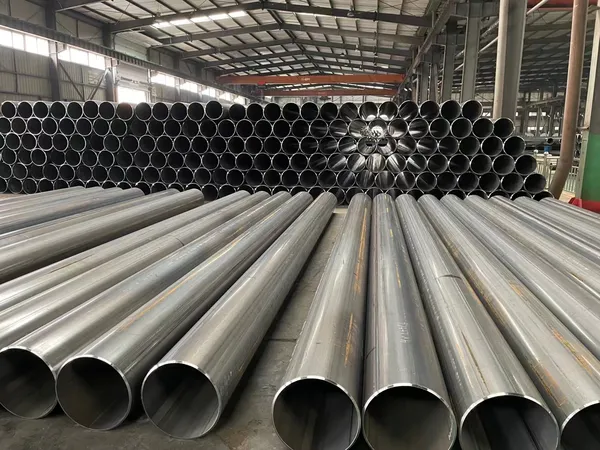

ASTM A335,P9,P91,P92,P11,P12,Alloy Tube,Seamless Alloy Steel Pipe

P9 steel pipe:

also known as ASTM A335 P9 or ASME SA335 P9, is a seamless, ferritic alloy-steel pipe used for high-temperature applications:

Composition:

seamless P9 steel pipe contains chromium and molybdenum, which improve its strength, oxidation resistance, and corrosion resistance.

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.015 max | 0.30-0.60 | 0.025 max | 0.025 max | 0.50 max | 4.00-6.00 | 0.45-0.65 |

Properties:

Alloy P9 steel pipe has a yield strength of 205 MPa, a tensile strength of 415 MPa, and an elongation percentage of about 30%.

| Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

| 415 min | 205 min | 30 min |

Applications:

A335 P9 pipes and tubes are used in the industries that require transportation of gas and fluid at high pressure and temperatures from the off-site or onsite to the plants. E.g: power plants, nuclear plants, petrochemical industries and industrial boilers need pipes to convey oils, water, steam and gas across from the site to the plant.

Manufacturing:

P9 seamless steel pipe can be manufactured through hot finishing or cold drawing. It is then finished with heat treatment, such as full or isothermal annealing, normalizing, or tempering.ASME SA335 P9 Seamless Pipes heat treatment

| P5, P9, P11, and P22 | |||

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

| P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] |

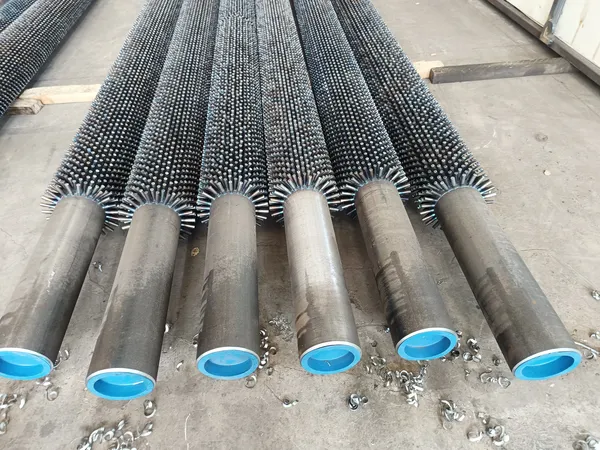

Surface treatments:

P9 steel pipe can be surface treated with phosphating, passivation, shot blasting, oil dip, or varnishing.

Coatings:

P9 steel pipe can be coated with black oil paint, anti-corrosion oil, or zinc to increase its resistance to corrosion.

Tolerances:

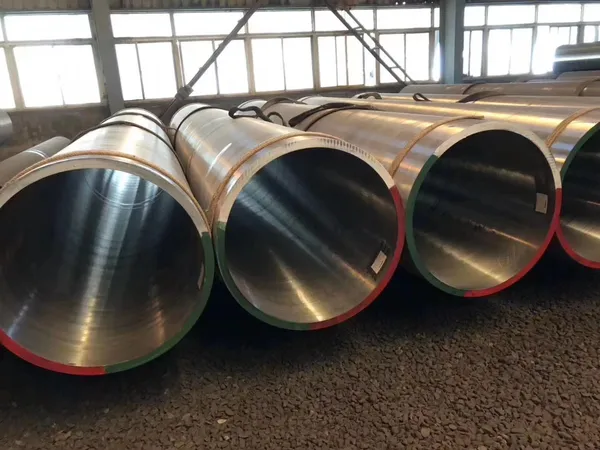

The inside diameter of P9 steel pipe should not vary more than 1% from the specified ID. The outside diameter has different tolerances depending on its size.ASME SA335 P9 Seamless Pipes Permissible Variation in Wall Thickness

| NPS [DN] Designator | Tolerance, % from Specified | |

| Over | Under | |

| 1/8 to 2 1/2 [6 to 65] incl., all t/D ratios | 20.0% | 12.5% |

| Above 2 1/2 [65], t/D < or = 5% | 22.5% | 12.5% |

| Above 2 1/2 [65], t/D > 5% | 15.0% | 12.5% |

| (t = Specified Wall Thickness; D = Specified Outside Diameter) | ||

Our stocks ASTM /ASME A/SA P9 Pipe, Heater Tubes, Fittings, Flanges from ½” NPS through 36″ NPS with wall thickness ranging from STD through XXS. Emphasis on our P9 inventory is our strength in the Heater Tube market. We are considered to have the largest inventory of P9 Heater Tubes. Heater Tubes typically range in sixes 4″ NPS through 16″ NPS from STD Wall Thickness through XXS. our stock also consists of Minimum Wall Thickness pipe as well as material certified to ASTM/ASME A/SA 213 which is required by some heater designs.because the mass stock,keep the fastest delivery to Clients.welcome to you Order and Inquiry.

Q