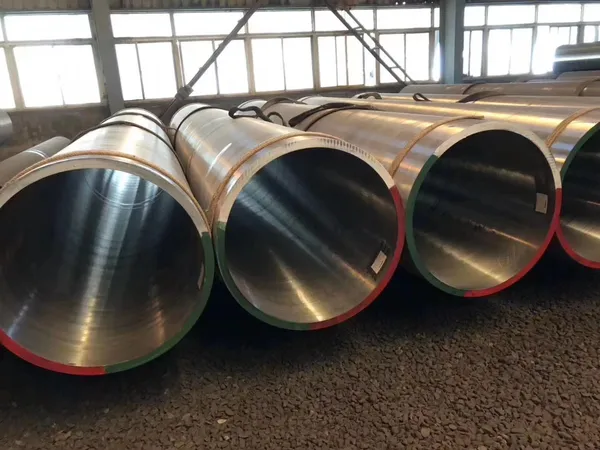

Alloy seamless pipe is made of high quality carbon steel, alloy structural steel and heat-resistant stainless steel material, hot-rolled (extrusion, expansion) or cold-rolled (pull) made.

Alloying elements:

The addition of Molybdenum(“Moly”)increases the strength of the steel and its elastic limit,enhances the steel resistance to wear,its impact qualities,and the hardenability.It also improves the resistance to softening,makes chromium steel less prone to embrittlement, and prevents pitting.

Chromium,a key element also for stainless steel alloys,prevents steel oxidation at elevated temperatures and increases the resistance of steel to corrosion.It enhances the tensile,yield,and hardness properties of low-alloy pipes at room temperatures.

Other alloying elements,present in various degrees in Alloy Pipes of all grades are:

1. Aluminum: decreases oxygen from steelmaking

2. Boron: used to produce fine grain size and enhance steel hardness

3. Cobalt: used to enhance the steel’s heat and wear-resistance

4. Manganese: gives better steel hardenability

5. Nickel: Enhances toughness, hardenability, and impact strength at low temperatures

6. Silicon: decreases oxygen, enhances hardenability and toughness

7. Titanium: prevents precipitation of chromium carbide

8. Tungsten: refines steel grain size and enhance the steel hardness, especially at high temperatures

9. Vanadium: gives steel enhanced fatigue resistance

As mentioned, low-alloy steels have a total amount of alloying elements below 5%; high alloy steel has a higher percentage of these elements.

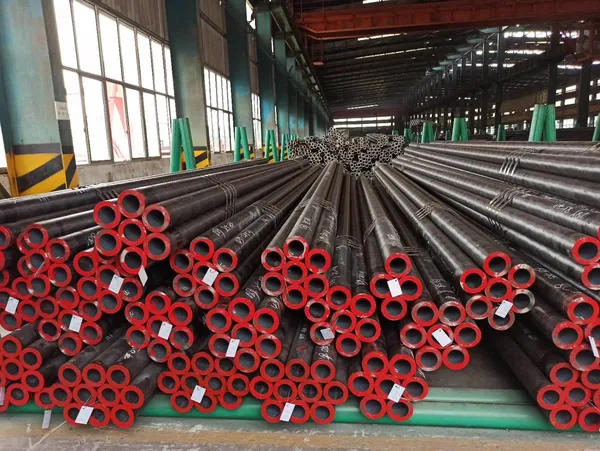

ASTM A335 P5,P9,P91,P92.Steel Pipe main using to Boiler,Tube boilers are broadly classified into two categories: water-tube boilers and fire-tube boilers.

Water circulates inside the tubes of a water-tube boiler and is heated outside by hot gases created by the furnace. With fire-tube boilers, hot gas travels through one or more tubes, heating the water surrounding them by thermal conduction.

Two types of boiler tubes transportation objects are different, but the overall test of the boiler tube’s high temperature resistance/high pressure resistance and corrosion resistance.

High temperature resistance: especially fire boiler tube, the temperature can reach hundreds of degrees or even higher, so then this environment, to ensure that the performance of the pipe will not change, the strength will not decline, can not produce cracks.

High-pressure resistance: Boiler Tubes in the work, in order to improve efficiency, often transported objects pressurized, which leads to the boiler tube must have sufficient high-pressure resistance. Guarantee that the pipe will not rupture and explode after the re-transported objects are pressurized.

Corrosion resistance: boiler tubes will be exposed to different environments, these substances will make the boiler pipe itself chemical properties change, especially water boiler tube may be scaling. So the boiler tube must have good corrosion resistance.