API 5L X52 PSL2 SEAMLESS PIPE,X52 GRADE PSL1 LINE PIPE,SUPPLIER OF API GRADE L360 X52 PIPE

API 5L X52 Pipe – API 5L X52 Pipe PSL-1/PSL-2, Carbon Steel Seamless API 5L X52 PSL 2 Pipe, API 5L X52 Pipe Supplier

“API 5L X52 PSL1 Pipe: High Strength, Durable and Flexible Pipeline Solutions for the Transportation of Oil and Gas,Leading Stockholder.”

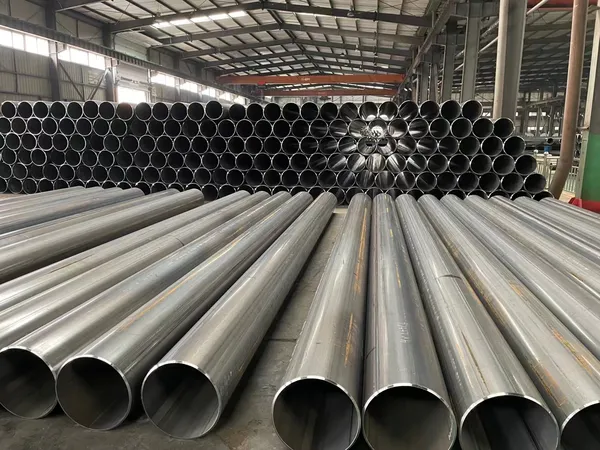

The American Petroleum Institute specification API 5L X52 PSL2 Pipe covers seamless and welded steel line pipe. This is steel pipe for pipeline transportation systems in the petroleum and natural gas industries. API 5L is suitable for conveying gas, water, and oil. Size range is limited only by manufacturer’s capabilities.

Grade X52 indicates 52000 PSI minimum yield strength and 66000 PSI minimum ultimate tensile strength.API 5L X52 pipe also called L360 Pipe, X52 (L360) named by minimum yield strength 52 Ksi (360 Mpa). It’s a medium grade in API 5L and isO 3183 specifications, used for oil and gas pipeline transmissions.

Specifications for API 5L adhere to the International Organization for Standardization isO 3183, which standardizes pipeline transportation systems within the materials, equipment and offshore structures for petroleum, petrochemical, and natural gas industries.

The technical committee authoring the standards recognized that there are two basic Product Specifications Levels (PSL) of technical requirements and therefore developed PSL 1 and PSL 2. PSL 1 is a standard quality for line pipe where PSL 2 contains additional chemical, mechanical properties, and testing requirements.

Grades covered by this specification are A25 ,A ,B (and the following “X” Grades), X42, X46, X52, X56, X60, X65, X70, X80. The two digit number following the “X” indicates the Minimum Yield Strength (in 000’s psi) of pipe produced to this grade.

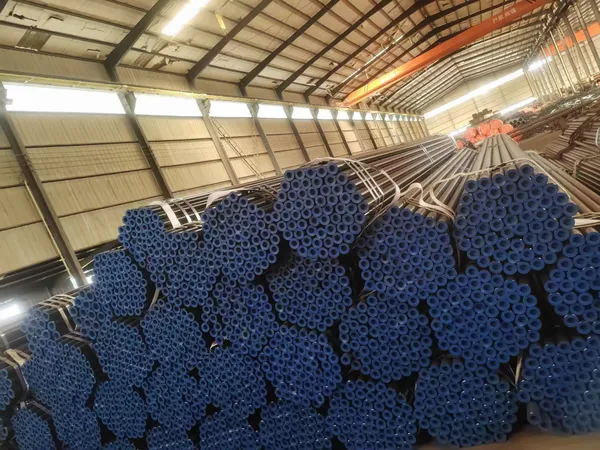

API 5L X52 Pipes are specially designed to handle the transportation of oil and gas under high pressure and temperature conditions. The production of these pipes places a strong emphasis on toughness and impact resistance, particularly for sour service and other demanding applications. Due to the high levels of sulphur present in sour wells, these pipes are particularly susceptible to stress corrosion. To mitigate this, manufacturers often apply anti-corrosion coatings such as oil, varnish, or black paint to the surface of the pipes. This additional layer of protection helps to enhance the corrosion resistance of the pipes, ensuring their longevity and reliability in harsh environments.

I can supply stocks a full range of API 5L X52 PSL-1 & PSL-2 line pipe in seamless.

API 5L X52 is a specification for pipeline steel pipes that are used in the transportation of oil and gas. The API 5L X52 specification covers both seamless and welded pipes and includes requirements for chemical composition, mechanical properties and dimensions such as pipe wall thickness, outer diameter and pipe schedule. The pipe is known for its high yield strength of 52,000 psi and is suitable for high-pressure applications. It has an equivalent ASTM specification A53 Grade B and EN10208 L360MB or GB/T9711 L360 and isO3183 L360 as grade.

API 5L X52 Pipe Supply Ranges and Sizes:

- API SPECS 5L Gr. X52 or L360

- Standard API 5L, ISO 3183

- Grade X52 or L360 (Suffix letter N, Q, M, R)

- Type Seamless Steel Pipe 21.3mm – 914 mm, 1/2” – 36”

- Pipe Wall Thickness Schedule SCH 10, SCH 20, SCH 30, SCH STD, SCH40, SCH60, SCH XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, SCH XXS of the standard

- Range of Length SRL, DRL, 5 meter to 14 meter

- Fixed Length 5.8 Meter, 6.0 Meters,20FT,11.8 Meters,12.0 Meters,40FT.

- Product Specification Level PSL1, PSL2, Sour

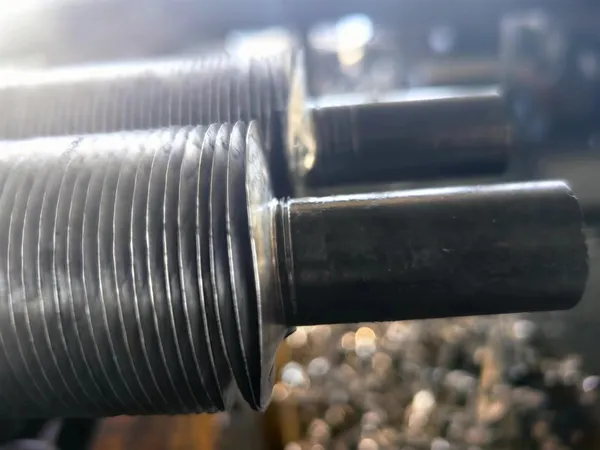

- Ends Plain, Beveled Ends, Threaded Ends

- Available Coating: Black Painting, Varnished, Anti-Rust Oil, FBE, 3PE/3LPE, 3PP, Galvanized

- Additonal Testing: NACE MR0175,NACE TM0177,NACE TM0284,HIC Test,SSC Test,H2 Service,Wet H2S Service, SOUR Service,etc.

- Certification: Completer Traceability EN 10204 3.1 and 3.2 Accredited Lab Testing,SGS,BV…