The company has obtained a number of certificates, API Spec 5L & API Spec 5CT certificate, ISO9001:2015 international quality system certificate, OHMS18001:1999 occupational health and safety management system certificate, ISO14001:2016 environmental management system certificate, ASME certificate and nuclear grade certificate, PED etc.

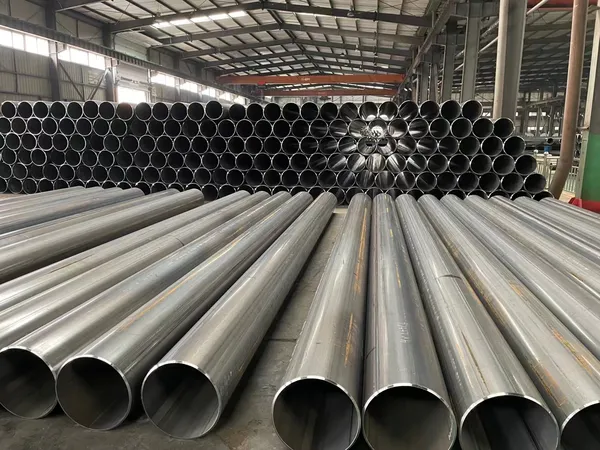

Hot Rolling Seamless Steel Line Pipe Manufacturing / Production processes:

Rolled Round Billets – Examination – Cut Off – Heating – Piercing – Elongation – Slight Tension Reducing – Straightening – Corp End Cutting Off – Visual Inspection – NDT – Hydrostatic Test – Ends Procession – Product Inspection – Painting and Marking – Packing – Warehousing

“Top seamless steel pipe manufacturers, with faster delivery, high quality and competitive prices! our company put the customer first, establishes pre-sales, on-sales and after-sales service standard,Our quality products are widely welcomed and highly applauded by both domestic and international customers.”

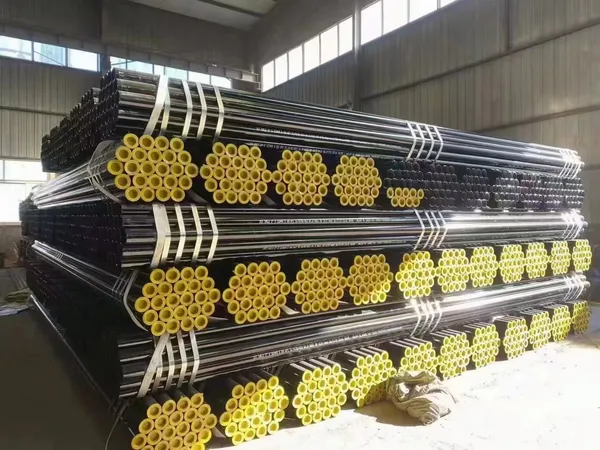

Our supply range for black carbon steel pipe:

Outer Diameter: 1/8” to 40” (10.3mm to 1016mm)

Thickness: SCH10 to SCH160 / XXS

Length: SRL, DRL, 20FT, 40FT, from 5 meter to 18meters, or customized.

Ends process: Plain Ends, Beveled Ends,Threaded Ends

Outside Coating: Blacking painting, Varnished, FBE, 3pp, 3PE/3LPE, Polyethylene layers coating

the company has its own independent testing center, within the ultrasonic testing, hydrostatic testing, eddy current testing, metallurgical analysis, universal testing instrument (mechanical performance detection), intergranular corrosion test, carbon and sulfur analyzer, spectrum analyzer, large hardness meter, impact test equipment to facilitate customer acceptance testing on the spot.

the company has its own independent testing center, within the ultrasonic testing, hydrostatic testing, eddy current testing, metallurgical analysis, universal testing instrument (mechanical performance detection), intergranular corrosion test, carbon and sulfur analyzer, spectrum analyzer, large hardness meter, impact test equipment to facilitate customer acceptance testing on the spot.

Cold Drawn (Rolled) seamless steel pipe manufacturing process:

Mother pipe (Normally for hot rolled pipe) – Inspection – Annealing – Ends Treatment (Hitting and Drilling hole) – Pickling – Grinding – Phosphorization (Annoit) – Cold Drawn (Rolled) – Degreasing and Cleaning – Heat treatment (Solution treatment) – Straightening – Hydrostatic test – Painting and Marking – Warehousing