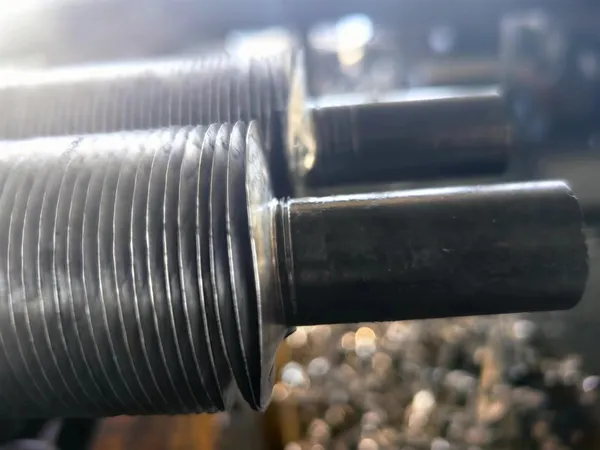

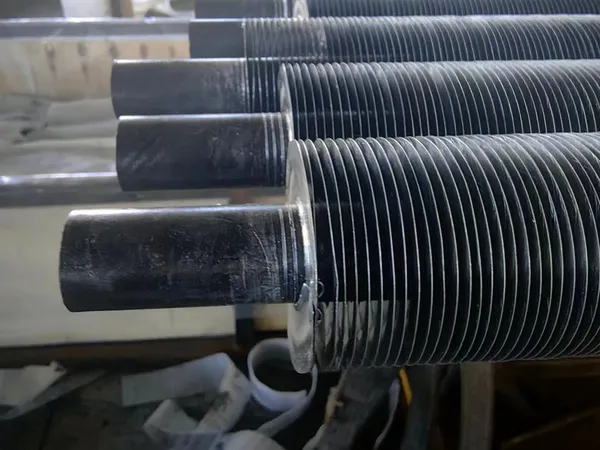

GROOVED FIN TUBE OR’G’FIN TUBE (EMBEDDED FIN TUBE ):-

The’G’FIN TUBE is also known as Embedded Fin Tube.This type of fin tube widely finds acceptance where the requirement is for higher operating temperature and relatively lower corrosive atmosphere

The fins are manufactured by embedding the fin strip into a groove formed on the base tube.The Fin is allowed to be placed in the groove and then the backfilling of the groove is carried out to ensure firm adherence of the fins to the base tubes.Because of the process this type of Fin Tube is also known as’G’Fin tube or Grooved Fin Tube.

The grooving,fin stack inserting and the backfilling processes are carried put simultaneously as continuous operation.Because of the back filling procedure the bond between the Fin material and the Base tube is one of the best.This ensures optimum Heat Transfer.

These Fin Tubes find application in AIR FIN COOLERS, RADIATORS etc.and are preferred in Industries like Power Plants,Chemical Industries,Petroleum Refineries,Chemical process Plants,and Rubber Plants etc.

“We can supply material on urgent delivery basis because of large stock.We use only Prime Quality base tube and Aluminum Material.The fin Tubes can be supplied with EN 10204 EN 3.1 and EN 3.2 certifications.We can provide Third Party Inspection from any reputed inspection agency.”

A192 Seamless Carbon Steel Aluminum Embedded Fin Tube

A192 Seamless Carbon Steel Bolier Tube ,Embedded Aluminum Cooling Fin Tube

ASTM A192 / A192M : Seamless Carbon Steel Boiler Tubes for High-Pressure Service

ASTM A210 / A210M : Seamless Medium-Carbon Steel Boiler and Superheater Tubes

ASTM A335: P5,P9,Seamless Alloy Steel Embedded Fluted Finned Tube

ASTM A213:TP304/304L,TP316 / TP316L Embedded Fin Tube of Stainless Steel Copper

What Are Finned Tubes?

Finned tubes are elongated flat tubes that are made of aluminum cladded carbon steel and are provided with brazed aluminum fins.These tubes are used in a series in heat exchangers.The advantage they offer over ordinary tubes is that the fins offer greater contact with the liquid outside.This quickens the exchange of heat between the liquid inside the tube and the one outside it.With a normal tube, the rate of exchange of heat would be much slower.

Finned tubes are available in different shapes.They are available as oval tubes, round tubes, and flat tubes.

What Are Their Uses?

Finned tubes are particularly useful in the case of air heat exchangers.In an air heat exchanger, the heat transfer is to take place between a liquid and gas. With the heat coefficient of the airside being lower, a finned tube can be exceptionally helpful.A finned tube increases the surface area and thus helps in faster heat transfer between the components.

Example of Fin Tube Heat Exchangers

Fin tube heat exchangers are used in household appliances and industrial heat exchangers. Fin tube heat exchangers are used in air conditioners and car radiators.The purpose of using a finned tube in an air conditioner is to cool the air passing through it.In a car radiator,it cools the liquid in the tube with the air passing through in crossflow.

Advantages of Using Finned Tubes

Finned tubes offer several advantages:

Increase Heat Transfer Rate

The fins in a finned tube increase the surface area of contact.This allows it to quicken the heat transfer rate.

Improve Heat Transfer Coefficient

In an ordinary tube,the outer surface area is just about the same or slightly different from the inner surface area. In such a case,the fluid with the lowest heat transfer coefficient will drive the entire heat transfer rate.A finned tube increases the surface area significantly.This is particularly helpful when the heat transfer coefficient of the fluid inside the tube is greater than that of the fluid outside the tube.

Reduces Size of the Equipment and Makes Project Cost Efficient

Finned tubes can significantly increase the surface area.The use of a finned tube can cut down the number of tubes used in an application. This results in a considerable reduction in the size of the equipment.In the long run,this can lead to a decrease in the cost of the project.