ERW is the abbreviation of straight seam high frequency electrofusion (resistance) welded pipe, and ERW is also called EFW.

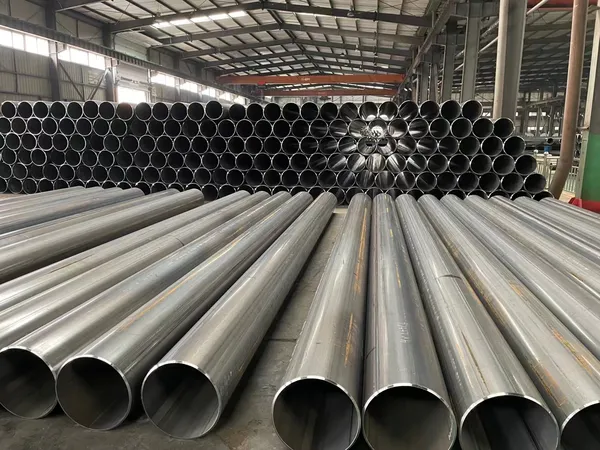

A welded pipe is manufactured by rolling a flat steel plate or strip into a cylindrical shape and welding the edges together along a seam. This process is generally more cost-effective and offers a wider range of sizes compared to seamless pipes.

Common Materials and Specifications:

Welded pipes are available in a variety of materials tailored to specific applications:

Carbon Steel: The most common and economical material, often used for construction and structural applications. Common specifications include ASTM A53 Grade B for general use and API 5L for line pipe.

Stainless Steel: Used in corrosive environments such as chemical plants, food industries, and for high-end decoration due to its excellent corrosion resistance. Common grades are Type 304 and Type 316.

Alloy Steel: Contains additional elements for higher strength, heat resistance, and corrosion resistance, used in demanding industries like aerospace and petrochemicals.

Galvanized Steel: Carbon steel pipe with a protective zinc coating to resist rust and corrosion, commonly used in water supply, HVAC systems, and general construction where corrosion is a concern.

Welded vs. Seamless Pipe Comparison:

| Feature | Welded Pipe | Seamless Pipe |

| Manufacturing | Formed from a flat strip/plate and welded along a seam. | Extruded from a solid billet, resulting in no seam. |

| Cost | Generally less expensive. | More expensive due to complex production. |

| Available Sizes | Available in a wider range of large diameters and long lengths.Higher dimensional accuracy and uniform wall thickness. | Limited to smaller diameters, although some large sizes are available via hot expansion. |

| Pressure Rating | Suitable for low to medium-pressure applications; weld seam is a potential weak point. | Stronger and can handle higher pressures and temperatures; ideal for critical applications. |

Manufacturing Process (2026 Standards):

The production of ERW pipe is highly efficient and automated, making it a cost-effective alternative to seamless pipe for various applications.

Forming: A continuous steel strip is fed through rollers that progressively bend it into a tube.

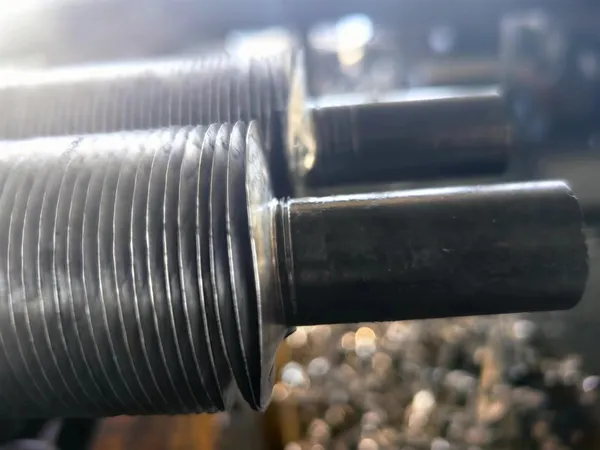

Welding: High-frequency current (HFW) heats the edges of the strip to a forge-welding temperature. Squeeze rolls then apply pressure to fuse the edges together.

Finishing: Excess weld material (bead) is removed from the interior and exterior to ensure a smooth surface. The pipe is then sized, straightened, and cut to length.

Testing: Rigorous non-destructive testing (NDT), such as ultrasonic and hydrostatic tests, is performed to verify the integrity of the weld.

ERW pipes are manufactured under several international standards depending on their intended use:

ASTM A53 (Grades A & B): The most common standard for general-purpose pressure transmission (steam, water, gas) and structural use.

API 5L: Standard for line pipe used in the oil and gas industry, ranging from Grade B up to high-strength X70.

ASTM A500: Specified for cold-formed structural tubing used in building frameworks and bridges.

ASTM A513: Standard for mechanical tubing, often used in automotive and industrial machinery.

Applications :

Energy: Transportation of oil, natural gas, and water in gathering and trunk lines.

Construction: Scaffolding, fencing, structural supports, and urban water/sewage systems.

Automotive: Used in exhaust systems, chassis components, and roll cages.

Infrastructure: Fire protection (sprinkler systems), piling for foundations, and city gas distribution.

We can produce diameter from 2″ to 30″, wall thickness from 2 mm to 18 mm, standard: API5L, PSL1, PSL2, ASTM A53, ASTM A252, EN10025, EN10217, ASTM A500, ASTM A 519, ASTM A530, etc., Steel grades: A, B, X42M, X52M, X60M, X65M, X70M, X80M, S355.S235JR, S235 G2H, S275, S275JR, S355JRH, S355J2H, St12, St13, St14, St33, St37, St44, ST52.

The company has its own independent testing center. In ultrasonic flaw detection, hydraulic flaw detection, eddy current flaw detection, metallographic analysis, etc., advanced production technology, perfect testing equipment and strict process control ensure the reliability and stability of quality.