Stardand :

ASTM A179,ASME SA179 Seamless cold-drawn Heat-Exchanger and Condenser Tubes

ASTM A179,ASME SA179 steel tubes covers minimum-wall-thickness, seamless cold-drawn low-carbon steel tubes for tubular heat exchangers, condensers, and similar heat transfer apparatus.

ASTM A179,ASME SA179 covers tubes 1/8 to 3 inch. [3.2 to 76.2 mm], inclusive, in outside diameter

ASTM A179,ASME SA179 Seamless Heat-Exchanger and Condenser Tubes – Details:

Manufacture: Seamless process ,cold drawn.

Wall thickness(WT): 2.0 mm——14.27 mm.

Outer diameter (OD): 12.7mm——76.2 mm

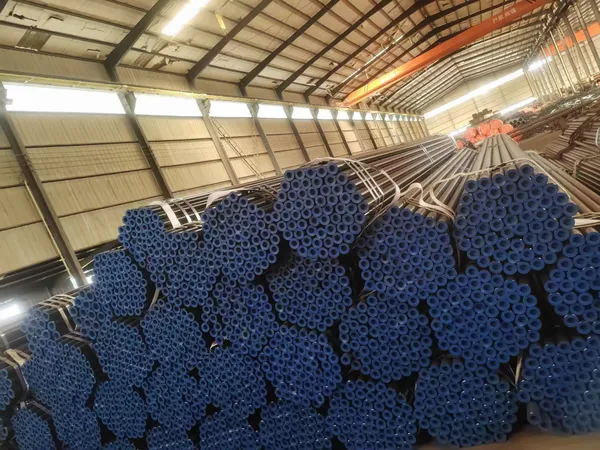

Length: 20FT or 40FT, specified length as required.

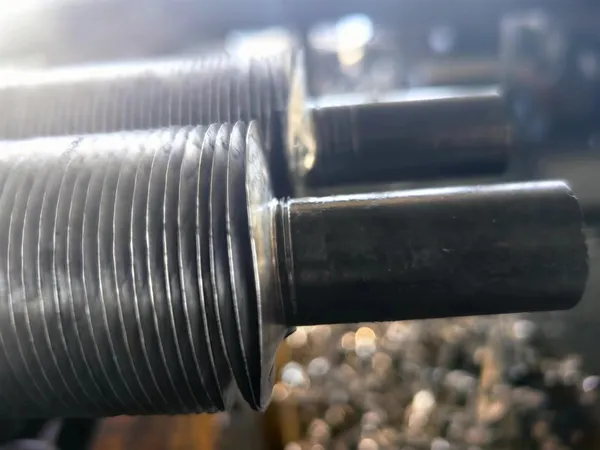

Ends: Plain End, Beveled End, Treaded

Additional Info:

Port of Shipment: Tianjin, China

Payment Terms: T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished (Outside only) to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

Manufacture:

Heat Treatment of ASTM A179,ASME SA179:

Chemical Composition of ASTM A179,ASME SA179 Seamless Heat-Exchanger and Condenser Tubes:

Material | Chemical Composition(%) | ||||

| C | Si | Mn | P | S | |

| ASTM A179 | 0.06-0.18 | ≤ 0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 |

Mechanical Propertie of ASTM A179,ASME SA179 Seamless Heat-Exchanger and Condenser Tubes:

| Grade | ASTM A179 |

| Tensile Strength(MPa) | ≥325 |

| Yield Strength(MPa) | ≥180 |

| Elongation,% | ≥35 |

| Hardness, HRB | ≤72 |

Note —Tubing smaller in outside diameter and having a thinner wall than indicated in this specification is available. Mechanical property requirements do not apply to tubing smaller than 1/8 in. [3.2 mm] in outside diameter or with a wall thickness under 0.015 in. [0.4 mm].

The Dimensional Tolerances of ASTM A179,ASME SA179 Seamless Heat-Exchanger and Condenser Tubes :

| Outside Diameter, in. [mm] | Wall Thickness, % | |||||||

| 0.095[2.4] and Under | Over 0.095 to 0.150 [2.4 to 3.8], incl | Over 0.150 to 0.180 [3.8 to 4.6], incl | Over 0.180,[4.6] | |||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

Seamless, Cold-Finished Tubes | ||||||||

Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Outside Diameter,in. [mm] | Permissible Variations, in. [mm] | |

| Over | Under | |

| Under 1 [25.4] | 0.004 [0.1] | 0.004 [0.1] |

| 1 to 1 1 ⁄ 2 [25.4 to 38.1], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [38.1 to 50.8], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50.8 to 63.5], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [63.5 to 76.2], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [76.2 to 101.6], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [101.6 to 190.5], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [190.5 to 228.6], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

Method of | Outside Diameter, in. [mm] | Cut Length,in. [mm] | |

| Over | Under | ||

Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] and over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] and over | 3 ⁄ 16 [5] | 0 [0] | |

Mechanical Tests Required:

(1) Flattening Test—One flattening test shall be made on specimens from each of two tubes from each lot or fraction thereof.

(2) Flaring Test—One flaring test shall be made on speci- mens from each of two tubes from each lot or fraction thereof.

(3) Flange Test—When specified as a substitute for the flaring test, for tubes having a wall thickness (actual mean wall) less than 10 % of the outside diameter, one test shall be made on specimens from each of two tubes

(4) Hardness Test—Rockwell hardness tests shall be made on specimens from two tubes from each lot.

(5) Hydrostatic Test—Each tube shall be subjected to the hydrostatic test, or a nondestructive electric test

Surface Condition:

Finished tubes shall be free of scale. A slight amount of oxidation will not be considered as scale.

Application:

ASTM A179,ASME SA179 seamless cold-drawn low-carbon steel tubes for tubular heat exchangers, condensers, and similar heat transfer apparatus.